Air-Automatic Heat Transfer Press

Description

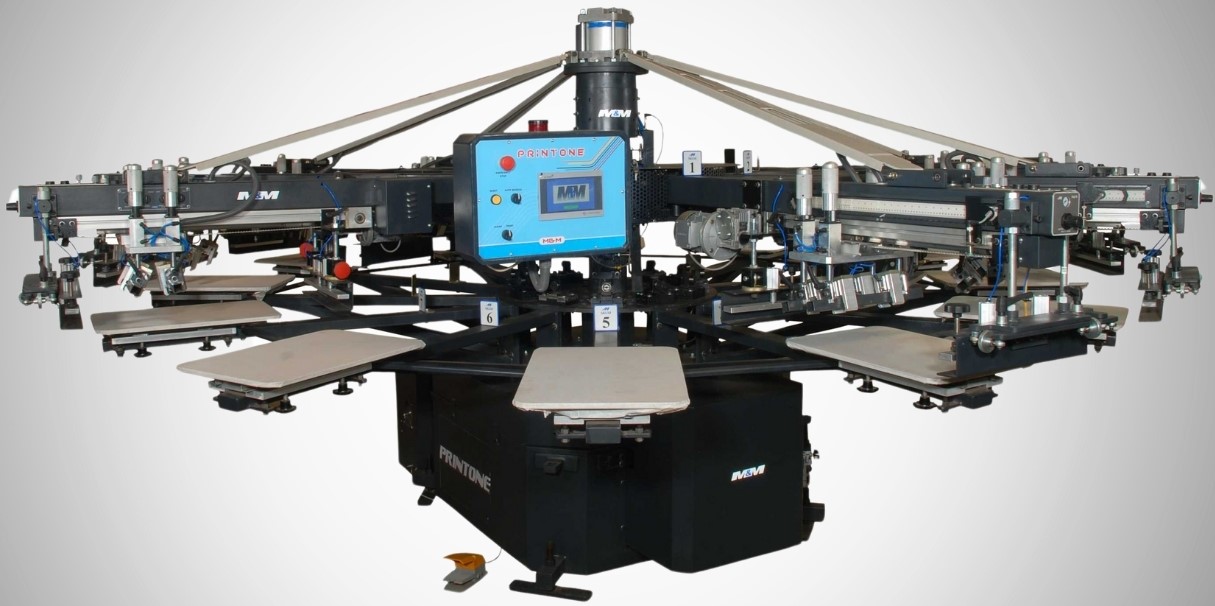

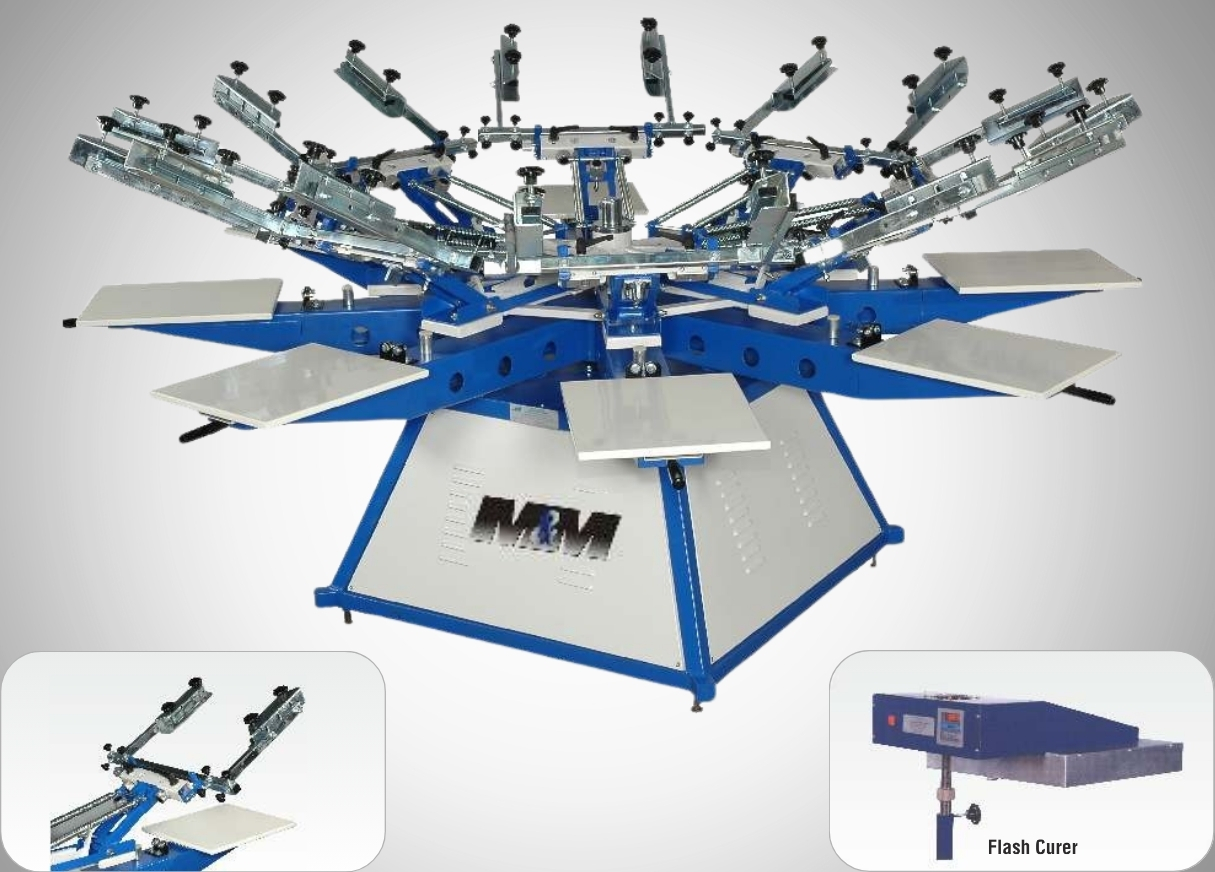

These presses considerably increase the productivity of heat transfer pressing by relieving the operator of important manual labour typically associated with manually clamping presses.

With smooth air-operated automated pressing at the touch of a button, these automatic presses eliminate any guesswork from the transfer process, replacing it with a large volume production of consistent and dependable heat pressed products.

There are two types of standard-sized automated presses. Which are shuttle press and swing-away models. The shuttle presses have a two-station layout, allowing the operator to load and unload one table while the other is under the heat platen. When the heat platen has finished pressing one of the tables, the other is moved under the heater block. This enables for the most efficient use of the heating block, with little time lost when no product is being pressed. The alternative design is identical to the Manual Swing-away presses, with the exception of being air-operated. The automated swing away presses offer easy tabletop operation with the simplicity and power of push button actuation.

Features

- Teflon coated even heat platens.

- Air assist for high production.

- Automatic program cycle for long production runs.

- Easier pressure adjustment system.

- Tough, heavy duty machine.

- Ideal for high productivity.

- Emergency release electric system.

- Dual timer setting.

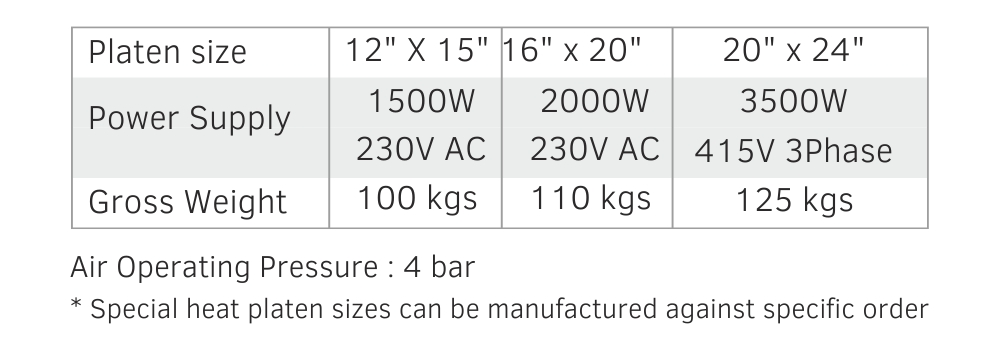

Specification